Geotextile fabrics are extremely versatile. They are used in many different types of construction projects, from roads to barns. Here’s what you need to know about when and how to use geotextile fabric.

What is a Geotextile?

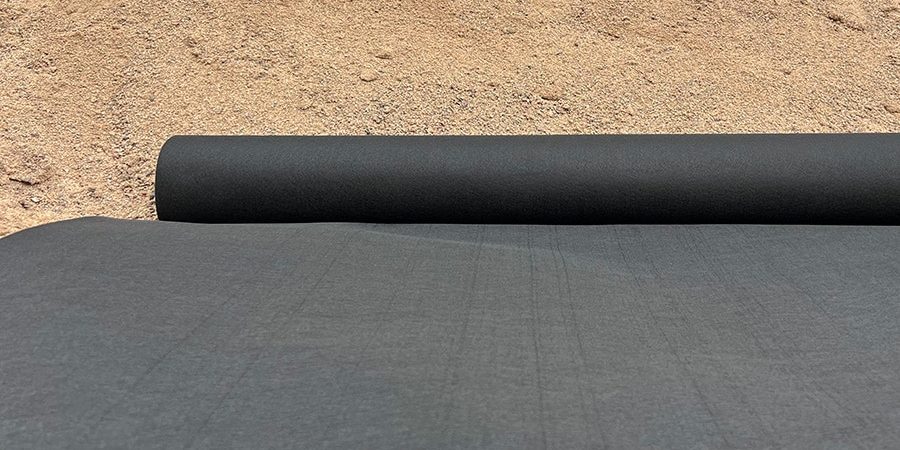

Geotextiles are fabrics used to separate soil layers. They are often used for building roads, barns, and other construction projects where separating materials, stability, and drainage solutions are needed.

Many fabrics can be used to separate soil, but geotextiles are the most effective. The fabric separates layers without compromising stability and permeability. For this reason, they are often used to construct horse areas.

What are Geotextile Fabrics Made of?

Geotextile fabrics are usually made from polyester, polypropylene, or synthetic fabrics. You can find geotextiles made from various materials, and each one serves a specific function and purpose.

Regardless of material, all geotextile fabrics are permeable. The fabric is designed to aid drainage systems by allowing water and other liquids to pass through the material. Determining what material geotextile you want depends on what type of drainage your project needs.

What’s the Difference Between a Woven and Non-Woven Geotextile?

There are two types of geotextiles: woven and non-woven. Each of these has different strengths and weaknesses and can serve different functions. Knowing how to use each type of geotextile can help you determine which fabric you’ll need for your project.

Woven Geotextiles

Woven geotextiles are made from synthetic fabrics that are tightly woven together. They tend to be stronger than non-woven fabric.

Woven fabrics are typically made from polypropylene, yarn, or similar fibers to create a stable and structured layer. Often, woven geotextiles are used to create a reinforced layer for heavier materials.

They tend to last longer than non-woven geotextiles. Usually, woven fabrics will last up to 50 years.

However, stronger materials can make the fabric less permeable than a non-woven option.

Non-Woven Geotextiles

Non-woven geotextiles are made from different fibers that are bound together by needles. Barbed needles are pushed through the fabrics, entangling them together with thousands of tiny holes.

Alternatively, non-woven fabrics can be made by bonding fibers together through a chemical process.

Non-woven fabrics provide the best drainage solution for projects. The fabric easily allows water and other liquid to travel through the material, preventing blockage and flooding.

These fabrics can have less strength than woven materials. For projects where fabrics are being used for reinforcement rather than drainage, woven fabrics would be more suitable.

Uses of Geotextiles

1. Separation

One of the primary uses of geotextile fabrics is separating materials. Both woven and non-woven are used to separate different materials and layers. Determining which type of fabric is ideal for your project depends on what material you are separating and why.

2. Stabilization

Geotextiles keep top layers level and stable by providing a permeable and set sublayer. Without them, top materials can compress and shift. Adding geotextile fabric prevents this from happening, creating a more stable and long-lasting result.

The ideal fabric type depends on what your top-level is made from. For heavier, load-bearing materials, like rocks and stones, woven fabric might be preferable.

3. Drainage

One of the most important features of geotextile fabrics is their ability to drain. This is crucial to prevent water build-up and flooding issues on your surface layer.

Both woven and non-woven materials allow drainage. But non-woven fabrics are more permeable, making them ideal for projects expecting higher water volume. They are often used when constructing rivers, canals, and other waterways.

Geotextiles in Horse Arenas

Geotextiles are often used for barns, stables, and horse arenas. When building a riding or dressage arena, geotextiles are a necessity. They serve three main functions, each of them ideal for horse riding.

First, they separate the subbase layer from the sand and footing. The subbase layer of an arena is made from compressed stones and creates a strong and level foundation. Over time, the sand and footing used to provide cushioning for horses can mix with the subbase, thus damaging the arena. Geotextile fabrics can be used to separate these two layers.

The fabric also creates additional stability for an arena. It works with the subbase layer to provide a more stable and level ground.

Drainage is also an important aspect of horse arenas. Without drainage solutions, flooding and water pooling can prevent using an arena and create long-term damage.

Final Thoughts

There are many construction projects that can benefit from geotextile fabrics. Not only are they more effective than alternative ground stabilizing options, but there are also more sustainable. They are lighter, thinner, and less expensive than other methods.

If you’re unsure if your project needs geotextiles, contact us for more information.