Homeowners spend an average of $500–$2,000 annually replacing gravel that migrates, sinks, or washes away from driveways, parking pads, and pathways. That perpetual maintenance cycle ends with a technology developed by the U.S. Army Corps of Engineers in 1975: the geocell ground grid. This honeycomb-shaped cellular confinement system reduces aggregate requirements by up to 75% while eliminating the mud, rutting, and erosion that plague residential properties year after year.

This article examines how geocell technology works, reviews documented performance results, and provides a practical guide for homeowners ready to solve their ground stabilization challenges permanently with BaseCore and BaseCore HD geocell systems.

What Is a Geocell Ground Grid? Understanding the Technology

A geocell ground grid is a three-dimensional cellular confinement system manufactured from high-density polyethylene (HDPE). When expanded, the collapsed panels form a honeycomb structure that confines fill materials—gravel, sand, soil, or concrete—within individual cells. This confinement prevents lateral movement of materials under load, creating a semi-rigid surface that distributes weight evenly and resists displacement.

The technology traces its origins to military necessity. According to Geosynthetics Magazine (February 2022), the U.S. Army Corps of Engineers Waterways Experiment Station (WES) developed cellular confinement systems in the late 1970s for building tactical roads over soft ground. Engineers devised methods for welding polyethylene strips into cellular structures, originally called “Sandgrid.”

Early testing proved decisive. A 1982 installation at Camp Blanding Joint Training Centre in Florida demonstrated that National Guardsmen could construct half a mile of road in just 25 working hours. The road successfully supported heavy military vehicle traffic, proving the technology viable for demanding applications.

Modern geocells like BaseCore and BaseCore HD maintain these engineering principles while incorporating improvements for residential use. BaseCore panels expand to cover large areas quickly, require no heavy equipment for installation, and deliver decades of maintenance-free performance.

How Geocell Technology Solves Common Residential Problems

The Gravel Driveway Dilemma

Traditional gravel driveways suffer from a fundamental engineering flaw: loose aggregate has no lateral confinement. When vehicles drive across, the tire pressure displaces stones horizontally. Over months and years, gravel migrates to edges, creates ruts in wheel paths, sinks into subsoil, or washes away during rainfall. The result is an endless cycle of purchasing and spreading new gravel.

Geocell confinement solves this through what engineers call “passive earth pressure.” When load is applied to fill material within a cell, the material attempts to move sideways but encounters the cell wall. This creates confining pressure that dramatically increases the gravel’s load-bearing capacity.

According to Backyard Bases documentation, using just 3 inches of BaseCore-confined gravel provides the same structural strength as 12 inches of traditional loose gravel. This 4:1 performance ratio means homeowners use 75% less material while achieving superior results. The confined gravel cannot migrate, sink, or wash away because each stone is held within its protective cell structure.

Research confirms these performance gains. Wikipedia’s Cellular Confinement page, citing studies by Bathurst and Jarrett (1988), notes that geocells performed better than single-sheet reinforcement methods and were more effective in reducing lateral spreading of infill under loading than conventional approaches.

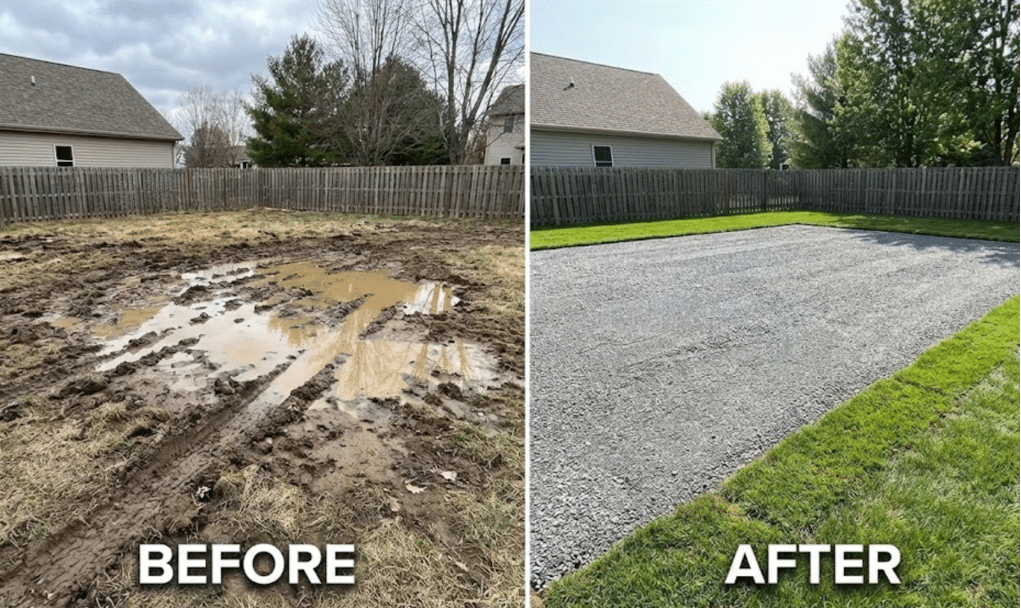

The Muddy Yard Problem

Every property has trouble spots—low areas that collect water, high-traffic zones near gates and doors, pet runs that turn to mud, or sections where grass simply won’t survive. These muddy patches create eyesores, track dirt into homes, and become unusable during wet seasons.

Backyard Bases’ guide on geocell applications identifies these high-traffic residential areas as ideal candidates for stabilization. The honeycomb structure lifts the surface above saturated soil, confines aggregate that promotes drainage, and prevents the churning action that creates mud in the first place.

The perforations in BaseCore cell walls serve a crucial function beyond simple drainage. These engineered openings create lateral drainage paths that prevent hydraulic pressure buildup while maintaining structural cell integrity. Water passes through freely without washing away the confined material—eliminating the pooling that creates mud while protecting against erosion.

Hillside Erosion Destruction

Sloped yards present unique challenges. Water runoff gains velocity as it travels downhill, gaining erosive power that carves channels, displaces soil, undermines retaining walls, and threatens foundations. Traditional solutions—concrete retaining walls, extensive terracing, rock armoring—often cost $10,000–$15,000 or more for moderate residential slopes.

Research published in Advances in Civil Engineering (April 2021) quantified geocell effectiveness on slopes. The study found that unsupported slopes showed the greatest soil erosion under various rainfall intensities, while geocell-reinforced slopes reduced erosion by 45–70%. When researchers combined geocells with organic reinforcement like wheat straw, erosion reduction reached 93%.

BaseCore HD can stabilize slopes up to 45 degrees when properly anchored with rebar stakes. The cell walls contain perforations that promote drainage while allowing vegetation roots to interlock between cells, creating living reinforcement that strengthens over time.

Backyard Bases case studies document a Colorado homeowner who faced annual washouts on a 40-degree slope behind their mountain home. Previous attempts with railroad tie terracing failed within two years as freeze-thaw cycles destroyed the wood structures. After installing 4-inch BaseCore HD geocells with crushed granite infill and native grass seeding, the slope remained stable through five years of spring snowmelt and summer thunderstorms. The total project cost of $3,500 proved far less than the $12,000 quoted for a retaining wall.

Measurable Outcomes: What Homeowners Can Expect

Material and Cost Savings

The economic case for geocell technology rests on documented material reductions. According to Backyard Bases, BaseCore confinement delivers a 4:1 performance ratio—3 inches of confined gravel equals 12 inches of loose gravel in load-bearing capacity.

For a typical 400-square-foot driveway extension project:

- Traditional approach: 12 inches of gravel depth = approximately 5 cubic yards of material

- BaseCore approach: 3-inch geocell with 2-inch cover = approximately 1.5 cubic yards of material

At average gravel prices of $50–$75 per cubic yard delivered, this represents $175–$260 in material savings on a single small project—often covering the cost of the BaseCore panels themselves.

A 2020 case study published in Geosynthetics Magazine examined a large-scale hybrid geocell reinforcement project showing 42.3% savings in granular fill volume and 22.8% savings in initial project cost overall. While this industrial project differs in scale, the underlying engineering principles deliver proportional savings for residential applications.

Labor and Time Efficiency

Installation speed represents a major advantage for DIY homeowners. Backyard Bases confirms that most residential installations can be completed in a single weekend with proper planning. The process requires no heavy equipment, no concrete forms, no curing time—just basic tools most homeowners already own.

The typical installation timeline:

- Site preparation: 2–4 hours (clearing, leveling, fabric placement)

- Panel expansion and anchoring: 1–2 hours per 200 square feet

- Fill placement and compaction: 2–4 hours depending on area size

Compare this to concrete alternatives requiring forms, mixing, pouring, finishing, and 7+ days of curing before use.

Durability and Lifespan

HDPE geocells resist UV degradation, temperature extremes, and chemical exposure. Backyard Bases documentation indicates properly installed BaseCore systems deliver 60+ years of service life. The material withstands temperature ranges from -40°F to 220°F, making it suitable for any U.S. climate.

This longevity contrasts sharply with:

- Loose gravel: Requires annual replenishment and periodic re-grading

- Wood mulch paths: Decomposes within 2–3 years

- Asphalt: Cracks, heaves, and requires sealing every 2–3 years

- Concrete: Cracks in freeze-thaw cycles, difficult and expensive to repair

BaseCore panels can even be removed and reinstalled in different locations if property needs change—try that with a concrete pad.

Top 10 Residential Applications for BaseCore Geocell

1. Gravel Driveways

Eliminate ruts, prevent gravel migration, and stop the annual replenishment cycle. BaseCore keeps aggregate locked in place regardless of traffic volume.

2. Parking Pads and Driveway Extensions

Create additional parking for RVs, boats, trailers, or guest vehicles without pouring expensive concrete. The permeable surface also helps with stormwater management.

3. Shed and Outbuilding Foundations

Build stable, level foundations for sheds, playhouses, greenhouses, and workshops without concrete footers. The drainage properties prevent moisture accumulation beneath structures.

4. Patio Bases

Create stable underlayment for pavers, flagstone, or gravel patios. The geocell structure prevents settling and shifting that plagues traditional sand-set installations.

5. Garden Pathways

Transform muddy garden paths into all-weather walkways. Fill cells with decorative gravel or allow grass to grow through for a natural appearance.

6. Slope and Hillside Stabilization

Stop erosion on problem slopes up to 45 degrees. Vegetated geocell installations blend into landscaping while providing permanent stabilization.

7. Dog Runs and Pet Areas

Eliminate muddy pet areas that track dirt into homes. The permeable surface drains quickly while providing firm footing for animals.

8. Gate and Entry Areas

Stabilize high-traffic zones around gates, doors, and walkway intersections where foot traffic concentrates and creates wear patterns.

9. Fire Pit and Outdoor Living Areas

Create stable, level surfaces for fire pits, outdoor furniture, and entertaining spaces without permanent concrete construction.

10. Drainage Ditch and Swale Protection

Prevent erosion in drainage channels while maintaining water flow capacity. Geocells hold aggregate or vegetation in place against flowing water.

Practical Installation Guide

Step 1: Site Assessment and Preparation

Successful BaseCore installation begins with proper site evaluation. Key considerations include existing drainage patterns, slope angle, soil type, and intended traffic load.

Excavate 3–4 inches below your desired finished surface height. This creates space for the geocell system and infill while keeping the completed surface level with surrounding areas. Remove all vegetation, rocks, and debris to reach stable subsoil.

For drainage, maintain at least a 2% slope (approximately 1/4 inch per foot) away from structures. This ensures water flows off the surface rather than pooling.

Step 2: Geotextile Fabric Installation

Backyard Bases strongly recommends placing geotextile fabric beneath the geocell. This fabric layer provides three critical functions:

- Separation: Prevents subsoil from mixing upward into your gravel fill

- Stabilization: Distributes loads more evenly across the subgrade

- Weed control: Blocks vegetation from growing up through the surface

Roll out fabric across the entire prepared area, extending 6–12 inches beyond the planned geocell footprint. Overlap seams by 8–12 inches to ensure complete coverage.

Step 3: Geocell Expansion and Anchoring

BaseCore panels arrive collapsed for efficient shipping. Position the first panel at one end of your project area with the collapsed panel oriented in your expansion direction.

Secure the starting edge with rebar anchor stakes through the outer cells. With one person holding the anchored end, have a second person pull the opposite end to expand the honeycomb structure fully.

Once expanded, drive additional anchor stakes around the perimeter and throughout the interior. Backyard Bases includes stakes with each panel—use all of them for maximum stability.

Connect multiple panels using the included connector clips or zip ties through the cell wall perforations. Proper connection ensures continuous load distribution across the entire installation.

Step 4: Fill Material Selection and Placement

Fill material choice determines performance characteristics:

Angular crushed gravel (3/8″ to 3/4″): The recommended choice for driveways, parking areas, and any surface receiving vehicle traffic. Angular edges interlock within cells for maximum stability. Avoid pea gravel or rounded stone, which can shift under load.

Decomposed granite or crusher fines: Excellent for pathways and patios where a smoother walking surface is preferred.

Topsoil: Appropriate for slope stabilization where vegetation establishment is the goal. Seeds can be broadcast over filled cells.

Fill each cell completely, then add approximately 2 inches of additional material above the cell tops. This cover layer protects the HDPE from UV exposure and creates your finished surface.

Step 5: Compaction

For gravel-filled applications, compaction ensures long-term stability. Use a plate compactor or hand tamper to consolidate the material, making multiple passes across the entire surface. Add additional fill to any areas where the BaseCore cell walls become exposed.

After compaction, your surface is immediately ready for use—no curing time required.

Choosing Between BaseCore and BaseCore HD

Backyard Bases offers two primary geocell product lines designed for different application intensities:

BaseCore: Ideal for lighter-duty applications including garden pathways, patio bases, light-duty parking pads, and gentle slopes. Handles pedestrian traffic, wheelbarrows, lawn equipment, and occasional vehicle use.

BaseCore HD: Engineered for demanding conditions including regular vehicle traffic, steeper slopes, areas with poor drainage, and any application where maximum stability matters. The high-density cell configuration delivers smaller cell sizes and greater structural strength.

Depth selection guide:

- 2-inch depth: Pathways, garden borders, light pedestrian areas

- 3-inch depth: Patios, light parking pads, private driveways with occasional use

- 4-inch and deeper: Regular vehicle traffic, RV/trailer parking, steep slopes, problem drainage areas

When in doubt, choose the next depth up—the additional stability is worth the modest cost difference.

Conclusion

The geocell ground grid represents nearly 50 years of engineering development, from military tactical roads to modern residential applications. Homeowners struggling with rutted driveways, perpetually muddy yards, washing gravel, and eroding slopes now have access to the same cellular confinement technology that supports heavy military vehicles.

The value proposition is straightforward: 75% less gravel, installation in a single weekend, and performance lasting 60+ years. For properties battling chronic ground problems, BaseCore eliminates the frustrating cycle of temporary fixes that fail within seasons.

Your next step: Visit BackyardBases.com to use the free BaseCore calculator, determine your square footage requirements, and select the geocell depth matching your application. A single weekend of work delivers decades of maintenance-free performance—transforming your property’s trouble spots into stable, functional ground for good.

Frequently Asked Questions

Can I install BaseCore geocell ground grid myself without professional help?

Yes. BaseCore systems require only basic tools: shovel, rake, hammer, and hand tamper or plate compactor. Backyard Bases confirms most residential projects complete in a single weekend with two people working together.

What depth BaseCore do I need for a gravel driveway?

For driveways with regular vehicle traffic, BaseCore HD in 3-inch or 4-inch depth provides optimal performance. Light-use driveways or occasional parking can use standard BaseCore at 3-inch depth.

How much gravel does BaseCore save compared to traditional installation?

BaseCore delivers a 4:1 performance ratio—3 inches of confined gravel equals 12 inches of loose gravel in structural capacity. This translates to approximately 75% less material required for equivalent performance.

Will BaseCore work on steep hillsides in my yard?

BaseCore HD stabilizes slopes up to 45 degrees when properly anchored with rebar stakes. Combined with geotextile fabric and vegetated infill, it provides permanent erosion protection at a fraction of retaining wall costs.

How long does BaseCore last before needing replacement?

HDPE geocell material resists UV degradation and temperature extremes from -40°F to 220°F. Properly installed BaseCore systems deliver 60+ years of service, and panels can be relocated if your property needs change.